What Is a Smart Control Valve? Understanding Its Role and Benefits in Modern Systems

In today’s world, where automation and precision control are paramount, smart control valves have emerged as an essential component in various industries, from manufacturing and HVAC systems to water management and energy applications. These valves represent a significant leap forward from traditional control valves, offering enhanced performance, efficiency, and ease of operation.

But what exactly is a smart control valve? How does it differ from conventional control valves, and why is it becoming so essential in modern systems? In this blog, we’ll explore the definition, working principles, benefits, and applications of smart control valves, shedding light on why they are a crucial part of the industrial automation ecosystem.

1. What is a Smart Control Valve?

A smart control valve is an advanced type of valve used in fluid or gas systems, which integrates automated control systems, sensors, and communication technologies to regulate the flow of media (liquids, gases, or steam) with high precision. Unlike traditional control valves that function solely through mechanical means (e.g., adjusting a valve’s opening with a manual actuator or basic pneumatic or electric signals), a smart control valve incorporates advanced electronics, sensors, and often, internet of things (IoT) technology for real-time monitoring and adjustments.

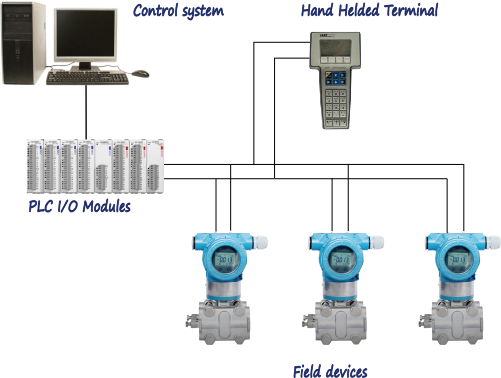

These valves are typically controlled by a central process controller or a programmable logic controller (PLC) that collects data from sensors in the system and adjusts the valve position to achieve optimal flow rates, pressures, or temperatures. In short, smart control valves are valves that are not only automated but also intelligent, capable of making adjustments based on real-time conditions and feedback.

2. How Do Smart Control Valves Work?

Smart control valves function in a dynamic and adaptive manner, continuously adjusting to changing system conditions. Their operation can be broken down into several key components and processes:

2.1 Actuator and Sensor Integration

At the heart of a smart control valve is its actuator, which is responsible for controlling the valve’s opening and closing. Traditional actuators are typically powered by electric motors or pneumatic signals, but in a smart control valve, the actuator is enhanced by integration with sensors that monitor key system parameters such as:

- Flow rate (the volume of fluid passing through the valve per unit of time)

- Pressure (the force exerted by the fluid inside the pipe)

- Temperature (the heat of the fluid passing through the valve)

- Level (in tank or vessel applications)

These sensors feed data back to a controller that processes this information in real time, adjusting the valve’s position to maintain the desired flow rate, pressure, or temperature.

2.2 Automation and Control

Smart control valves are designed to interact seamlessly with a wider automation system, often connected to a central SCADA system (Supervisory Control and Data Acquisition), PLC (Programmable Logic Controller), or a DCS (Distributed Control System). These control systems continuously process data from multiple sensors and control devices, allowing operators to adjust the valve’s settings remotely through a central dashboard.

In more advanced systems, smart control valves can self-calibrate, predict failure points, and adjust to external factors such as changes in the environment or system pressure. With IoT technology, some systems even allow users to monitor the valve’s performance and make adjustments remotely using cloud-based platforms or mobile applications.

2.3 Data-Driven Adjustments

Smart valves use algorithms to make intelligent, data-driven decisions. Based on the real-time data received from sensors, the valve’s controller may automatically adjust the valve’s position or open and close it in a precise manner, depending on the conditions and system requirements. These adjustments help maintain system stability, efficiency, and safety.

For example, if a smart control valve is installed in a water distribution system, it will monitor water pressure and flow rates in real-time and adjust the valve position to ensure that the system operates within desired parameters. If there’s a sudden drop in pressure or a potential leak, the valve can be adjusted automatically to mitigate the issue.

3. Benefits of Smart Control Valves

Smart control valves offer a host of advantages over traditional, manual valves. Below are some of the most significant benefits:

3.1 Increased Efficiency

The ability to precisely control flow, pressure, and temperature leads to significant efficiency improvements. Smart valves adapt to changing conditions in real time, ensuring optimal performance at all times. This reduces energy waste, downtime, and excess wear on equipment, ultimately leading to cost savings and better resource management.

For example, in industrial processes, controlling the flow rate more accurately ensures that resources (such as steam, water, or chemicals) are used in the most efficient manner, helping to reduce operating costs.

3.2 Improved Process Control

Smart control valves allow for better process control because they can adjust automatically to meet pre-set conditions. This level of automation reduces human intervention, decreases the risk of errors, and maintains system parameters within safe operating limits. Whether it’s controlling a heating or cooling system, chemical processing, or water treatment, the precise control offered by these valves leads to improved consistency and reliability.

3.3 Real-Time Monitoring and Remote Access

One of the most notable features of smart control valves is their real-time monitoring capabilities. Sensors embedded in the valve and connected to a control system provide live data on the valve’s performance, system conditions, and flow characteristics.

Moreover, these valves can be monitored remotely through cloud-based platforms, allowing operators to check their status, make adjustments, or even perform diagnostics from anywhere in the world. This remote accessibility helps businesses with multiple facilities or geographically distributed assets streamline their operations and improve response times to issues.

3.4 Predictive Maintenance and Failure Prevention

By continuously monitoring system data, smart control valves are able to provide valuable insights into the health of the system. The data collected by the sensors can be analyzed to predict potential failures or maintenance needs before they become serious issues.

For example, if the valve is experiencing irregular flow or unusual pressure drops, the system may detect these anomalies and send a warning signal to the operator, preventing more significant damage. This ability to predict and prevent failures leads to reduced downtime and lower maintenance costs.

3.5 Enhanced Safety

Smart control valves improve safety by ensuring that systems remain within safe operating parameters. In applications involving high-pressure systems, hazardous chemicals, or critical infrastructure, maintaining proper flow and pressure is vital for preventing accidents, spills, or system failures.

Through precise control and automated adjustments, smart control valves help to maintain optimal system conditions and mitigate the risk of unsafe operations. In critical applications such as oil and gas, water treatment, and industrial manufacturing, this enhanced safety is paramount.

3.6 Environmental and Regulatory Compliance

In many industries, regulatory bodies impose strict requirements for environmental protection and safety standards. Smart control valves play a crucial role in helping businesses meet these regulations by ensuring that systems are operating within legal limits.

For instance, in water management, smart control valves can adjust the flow of water in compliance with environmental regulations. Similarly, they help ensure that emissions, energy use, and waste outputs remain within regulatory limits, which is crucial for compliance and avoiding costly fines.

4. Applications of Smart Control Valves

Smart control valves are used in a wide range of industries and applications. Here are a few examples:

4.1 HVAC Systems

In HVAC systems, smart control valves are used to regulate the flow of water or refrigerants in heating and cooling processes. They ensure the desired temperatures and airflow are maintained efficiently, improving energy savings and occupant comfort. These valves can automatically adjust in response to changes in demand or environmental conditions, providing continuous, optimal performance.

4.2 Water Distribution and Wastewater Treatment

Smart control valves play a critical role in managing water distribution systems, controlling the flow of water and pressure in pipelines. They help optimize water usage, prevent pressure fluctuations, and ensure that water treatment processes are efficient and compliant with environmental standards.

In wastewater treatment plants, these valves are used to regulate the flow of chemicals, air, or water to control the purification process, ensuring optimal treatment and minimizing waste.

4.3 Oil and Gas

In the oil and gas industry, smart control valves are essential for managing the flow of gases and liquids under high-pressure conditions. These valves are used in pipelines, refinery systems, and offshore platforms to maintain safe and efficient operations. Smart valves ensure that systems remain stable, reducing the risk of leaks, spills, or other accidents.

4.4 Chemical and Pharmaceutical Manufacturing

In chemical and pharmaceutical manufacturing, precise control of fluids and gases is critical. Smart control valves regulate the flow of chemicals through various stages of production, ensuring that processes remain consistent and meet quality standards. These valves also help maintain safety by preventing over-pressurization or improper chemical concentrations.

4.5 Energy Production

In energy production, particularly in steam boilers and power plants, smart control valves are used to regulate the flow of steam and gases. They help optimize energy use, improve system stability, and maintain safe pressure levels within boilers and turbines, ensuring efficient energy production.

5. Conclusion

A smart control valve represents a significant advancement over traditional mechanical valves, offering enhanced precision, automation, and efficiency. By integrating real-time monitoring, data analytics, and adaptive control, smart control valves optimize performance, reduce operational costs, and improve system safety and reliability. Whether used in industrial manufacturing, HVAC systems, water treatment, or energy production, these valves are playing a crucial role in the modern era of automation and smart technology.