How to Select the Best Water Flow Meter for Your Application

Choosing the right water flow meter matters for accurate measurement and smooth operation. Many users face problems like picking the wrong flow meter technology or not thinking about future needs. You might also see mistakes when sizing the meter or focusing only on the lowest price. When you match the flow meter to your fluid and process, you avoid wasted time, extra costs, and unreliable results. A careful, step-by-step selection helps you find the best water flow meter for your application.

Water Flow Meter Types and How They Work

Understanding the main water flow meter types helps you choose the right tool for your needs. Each type measures liquid flow in a different way. The table below shows how common flow meter types work:

| Water Flow Meter Type | Measurement Principle / How It Measures Flow |

|---|---|

| Positive Displacement Flow Meters | Use a wheel or gear that spins as liquid flows; the spin rate is proportional to flow velocity, converted to flow rate. |

| Vortex Volumetric Flow Meters | An obstruction creates vortices in the liquid; the frequency of vortices is measured to determine flow rate. |

| Ultrasonic Flow Meters | Two sensors on pipe exterior send and receive ultrasonic pulses; flow rate is calculated from the time delay between pulses. |

| Magnetic (Electromagnetic) Meters | Generate a magnetic field; electrodes measure voltage induced by conductive fluid flow to calculate flow rate. |

| Turbine Flow Meters | A turbine with a magnet spins as fluid flows; a pickup coil detects rotations, converting pulses to flow rate. |

| Differential Pressure Meters | Measure pressure drop across a restriction; flow rate is calculated from the pressure difference. |

Mechanical Flow Meters

Mechanical flow meters use moving parts to measure liquid flow. You often see these meters in older systems or where cost is a big concern. They include positive displacement and turbine types. These meters directly measure the volume of water passing through. You do not need complex calculations. Mechanical flow meters work well with clean water and high-viscosity fluids. They are less sensitive to changes in flow profile, so you do not need long straight pipes. However, moving parts can wear out, especially if the water has dirt or debris. This means you need regular maintenance. You may also notice a pressure drop in your system because of the mechanical parts. Mechanical flow meters are reliable and cost-effective, but they do not offer advanced features like digital communication.

Tip: Use mechanical flow meters when you want a simple, robust, and affordable solution for clean water or thick liquids.

Electromagnetic Flow Meters

Electromagnetic flow meters, also called magnetic flow meters, use a magnetic field to measure liquid flow. When water flows through the meter, it creates a voltage. Electrodes pick up this voltage and convert it into a flow rate. Magnetic flow meters have no moving parts, so you get less wear and longer life. You can use them for both clean and dirty water, even if the water has solids or is thick. These meters give you high accuracy, often within ±0.5% of the true value. Magnetic flow meters work best with conductive liquids, such as water and wastewater. You often find them in water treatment, chemical plants, and food factories. They need electricity to work, but they require little maintenance.

- Magnetic flow meters are ideal for:

- Measuring water with suspended solids

- Applications needing high accuracy

- Situations where you want low maintenance

Ultrasonic Flow Meters

Ultrasonic flow meters use sound waves to measure how fast water moves. Two sensors attach to the outside of the pipe. They send and receive ultrasonic pulses. The meter calculates the flow rate by measuring the time it takes for the pulses to travel between the sensors. You do not need to cut the pipe or stop the flow to install these meters. Ultrasonic flow meters work well for clean water and can handle a wide range of flow rates. They offer high accuracy, often within ±1% of the actual flow. Some models reach even better precision. You can use ultrasonic flow meters for temporary checks or permanent setups. They are a good choice when you want a non-invasive, accurate, and flexible solution for measuring liquid flow.

Vortex Flow Meters

Vortex flow meters help you measure liquid flow by using a bluff body, also called a shedder bar, placed in the path of the fluid. When water or another fluid passes the shedder bar, swirling vortices form behind it. The meter detects the frequency of these vortices, which matches the speed of the fluid. You can use vortex flow meters for many fluids, including water, steam, glycol mixtures, solvents, and acids. These meters work well in industries like chemical, food and beverage, energy, and oil and gas.

- Vortex flow meters have no moving parts, so you get a leak-free design and less maintenance.

- You can measure liquids, gases, and steam with high accuracy.

- Multi-variable vortex meters also measure temperature and pressure, giving you compensated mass flow readings.

Note: Vortex flow meters do not work well with high-viscosity fluids, slurries, or fluids that coat or crystallize. You need straight pipe runs for best results.

You can rely on vortex flow meters for clean water and many other liquid flow applications. They offer a strong choice among water flow meter types when you want durability and flexibility.

Turbine Flow Meters

Turbine flow meters use a spinning rotor inside the pipe to measure liquid flow. As water moves through the meter, it turns the turbine. The speed of the turbine matches the flow rate. You get a pulse signal from the spinning rotor, which the meter converts into a flow reading. Turbine flow meters work best with clean water and low-viscosity fluids.

- You need to check bearings often, lubricate them, and replace them when worn.

- Corrosion checks help you avoid damage to the meter and your system.

- Filters or strainers keep debris out and protect the turbine.

- Regular cleaning keeps the meter working well and prevents debris from blocking the rotor.

- Calibration once a year helps you keep accurate readings.

If you install turbine flow meters in clean water systems, you can expect them to last for decades with minimal maintenance. In dirty or corrosive applications, you need more frequent checks and cleaning. Good installation and stable flow conditions help you get reliable measurements and a long service life.

Positive Displacement Flow Meters

Positive displacement flow meters measure liquid flow by trapping and counting small, fixed volumes of fluid. Internal parts like gears or pistons move as water flows through the meter. The movement matches the flow rate, so you get a direct and accurate reading. These meters work well with many fluids, including thick liquids and low flow rates.

- The meter uses tight seals and rotating parts to prevent fluid slippage.

- You get high accuracy, even at low flow rates, because the meter counts each volume of liquid.

- Linearity can be as tight as ±0.075%, and repeatability can reach 0.02%.

- You can use positive displacement meters for water, oils, and other viscous fluids.

Tip: Regular maintenance and calibration help you keep your meter working at its best. Remove gas bubbles and avoid damage to seals for top accuracy.

Positive displacement flow meters stand out among flow meter types for their precision in low flow and high-viscosity liquid flow applications. You can trust them for reliable readings in many water flow meter types.

Paddle Wheel Flow Meters

Paddle wheel flow meters help you measure liquid flow by using a spinning paddle inside the pipe. As water moves, the paddle turns. The meter counts the spins to show how much liquid flows through the pipe. You often see these meters in municipal water systems and irrigation setups.

When you install a paddle wheel flow meter, you need to follow some important steps:

- You must have straight pipe runs: 10 times the pipe diameter before the meter and 5 times after it.

- The meter works best with clean or lightly dirty fluids. Avoid using it with slurries or very dirty water.

- You can choose between in-line and insertion types. Insertion meters need special fittings, like saddle or welded fittings, to seal the sensor.

- Installing the meter usually means tapping the pipe and inserting the probe. This process works well for retrofitting older systems.

- The meter measures liquid flow in a small part of the pipe, so steady flow helps you get accurate results.

- Maintenance is easy. You only need to check the paddle for debris from time to time.

Tip: Proper installation and regular inspection keep your paddle wheel flow meter working well for years.

Mass Flow Meters

Mass flow meters measure the mass of liquid flow, not just the volume. You often use these meters in chemical plants, food factories, and places where knowing the exact mass is important. The most common type is the Coriolis mass flow meter.

Here is a quick comparison between mass flow meters and volumetric flow meters:

| Aspect | Mass Flow Meters | Volumetric Flow Meters |

|---|---|---|

| Measurement Principle | Measure mass of fluid per unit time | Measure volume of fluid per unit time |

| Influencing Factors | Fluid density | Fluid compressibility, temperature, and pressure |

| Common Technologies | Coriolis, thermal mass, differential pressure meters | Turbine, positive displacement, ultrasonic meters |

| Typical Applications | Chemical reactions, combustion, mass balancing | Water distribution, HVAC systems |

You use mass flow meters when you need to know the exact amount of material moving through your system. These meters give you both the speed and density of the liquid flow. This feature makes them perfect for processes where the mass, not just the volume, matters. Volumetric flow meters, on the other hand, work well for water distribution and other systems where you only need to measure how much space the liquid flow takes up.

Typical Applications for Water Flow Meter Types

Residential and Commercial Water Measurement

You often see water flow meters in homes and businesses for tracking water use and supporting accurate billing. The most common residential water meter is the mechanical type, such as positive displacement or turbine meters. These meters measure the flow rate of water by counting the movement of internal parts. You get reliable results at low and medium flow rates, which matches typical residential needs. Mechanical meters are affordable, but you need to check them for wear and tear.

Ultrasonic water meters have become popular in residential and commercial settings. They use sound waves to measure water speed, so you do not need to cut pipes for installation. This feature makes them great for retrofits. Electromagnetic meters also work well in commercial buildings. They offer high accuracy and need little maintenance because they have no moving parts.

| Water Meter Type | Common Use | Key Benefit for Billing |

|---|---|---|

| Positive Displacement | Residential | Accurate at low flow, reliable |

| Turbine | Commercial | Handles high volume, real-time data |

| Ultrasonic | Residential/Commercial | Non-intrusive, accurate, long life |

| Electromagnetic | Commercial | High accuracy, remote monitoring |

Tip: Choose a residential water meter that matches your flow needs and supports automated billing for easy management.

Industrial Process Control

In industrial settings, you need a flow meter that matches your process and fluid type. You must think about the fluid’s properties, such as if it is clean, dirty, or corrosive. You also need to know the flow range, pipe size, and the level of accuracy you want. Many industrial applications use electromagnetic or ultrasonic meters. These meters handle a wide range of fluids and give you precise flow measurement. You can connect them to control systems for real-time monitoring and billing.

You should also look for meters that can handle high pressure and temperature. Some flow meters offer smart features, like data logging and wireless communication. These features help you track the flow rate of water and spot problems early.

- Key factors for industrial flow applications:

- Fluid type and compatibility

- Required accuracy and output signals

- Installation and maintenance needs

- Integration with billing and monitoring systems

Irrigation and Agriculture

When you measure water for irrigation or farming, you face tough conditions. Water may carry dirt, sand, or chemicals. You need a water flow meter that can handle these challenges. Magnetic flow meters work well in these environments. They measure flow without moving parts, so you do not worry about clogs or frequent repairs. These meters also have strong enclosures that protect them from weather and rough handling.

Mechanical meters can work in clean water, but they may wear out faster in dirty or sandy water. Magnetic meters give you better accuracy and last longer. You can install them above or below ground, even in remote fields. This makes them a smart choice for flow measurement in agriculture.

- For irrigation and agriculture, consider:

- Water quality and debris

- Durability and maintenance

- Accurate billing for water use

- Ease of installation in remote locations

Water Treatment and Distribution

You play an important role in water treatment and distribution by choosing the right flow meter for your application. Accurate flow measurement helps you control chemical dosing, track water quality, and manage system performance. You often see electromagnetic flow meters in water treatment plants. These meters work well with conductive liquids, including treated water and wastewater. They offer high accuracy and need little maintenance.

Ultrasonic flow meters also help you monitor flow rates in large pipes. You can install these meters without cutting the pipe, which saves time and money. You use them for temporary checks or permanent monitoring. Vortex flow meters measure flow in systems with changing temperatures and pressures. You rely on them for steam and hot water applications.

You need to think about installation space, pipe size, and water quality. Dirty water or water with chemicals can damage some meters. You should choose meters with corrosion-resistant materials for harsh environments. Regular monitoring helps you spot leaks, track usage, and keep your system running smoothly.

Tip: Select a flow meter that matches your water quality and installation needs. This choice helps you maintain accurate monitoring and avoid costly repairs.

Specialized or Challenging Environments

You face unique challenges when you measure flow in specialized or tough environments. Space and weight limits can make installation hard, especially in retrofit systems. Some meters need long straight pipe runs, but you may not have enough room. This can affect accuracy and make installation difficult.

Changes in fluid properties, like temperature and salinity, can impact ultrasonic meter accuracy. Algae or sediment buildup can lower performance. Electromagnetic meters need short straight runs and give good accuracy, but fouling and low flow rates can reduce their reliability. You must balance accuracy, reliability, and installation constraints to meet regulations and operational needs.

Extreme temperatures, vibrations, and corrosive media can damage flow meters. You should use meters designed for harsh conditions or add protective measures like shielding and temperature jackets. Low-flow conditions challenge accuracy, so you need meters with wide turndown ratios and proper calibration. Turbulent flow causes disturbances, but advanced technologies like ultrasonic and Coriolis meters help you get stable readings.

You must also consider system integration. You need meters that work with your existing systems and handle variable flow rates, temperatures, and salinities. Reliable communication protocols help you manage data and support monitoring flow rates.

Common challenges in specialized environments:

- Space and weight constraints limit installation options.

- Fluid property changes affect meter accuracy.

- Fouling and sediment buildup degrade performance.

- Extreme temperatures and vibrations require special designs.

- Corrosive media demand resistant materials.

- Pulsating and turbulent flows need advanced meter technologies.

- Limited straight pipe runs distort flow profiles.

- System integration and data management add complexity.

Note: Always select a flow meter that fits your environment and operational needs. This decision helps you achieve reliable monitoring and meet regulatory standards.

Step-by-Step Flow Meter Selection Criteria

Identify Fluid Properties (Clean, Dirty, Viscous, Conductive)

You need to start your flow meter selection by looking at the fluid you want to measure. Fluid properties play a big role in how well a meter works. Clean water is easy to measure, but dirty water, viscous liquids, or fluids with solids can make things harder. Some meters work best with clean water, while others handle thick or dirty fluids better.

Key fluid properties to check include temperature, pressure, density, viscosity, and chemical composition. These factors affect how accurate your readings will be. For example, high temperature or pressure can change the density of your fluid. If you measure gases, you must watch for changes in density caused by temperature and pressure. Some meters, like Coriolis types, measure mass flow directly and do not need extra compensation for these changes.

You also need to think about corrosion and deposits. If your fluid contains chemicals that can damage the meter, choose materials that resist corrosion. Viscous fluids or those with solids may clog some meters, so pick a type that can handle these challenges. Positive displacement meters work well with thick liquids, while ultrasonic and electromagnetic meters resist scaling and deposits.

Here is a table to help you match fluid properties with recommended meter types:

| Fluid Property | Importance and Impact on Flow Measurement | Recommended Flowmeter Types |

|---|---|---|

| Temperature & Pressure | Affect fluid density and viscosity; cause measurement errors if uncompensated; influence material choice. | Coriolis, differential pressure, electromagnetic, ultrasonic |

| Density | Critical for gases due to variation with temperature and pressure; less variable for liquids. | Thermal mass, Coriolis (for gases); differential pressure, volumetric (for liquids) |

| Viscosity | Influences flow resistance and accuracy, especially for liquids with high viscosity. | Coriolis, electromagnetic, positive displacement |

| Chemical Corrosion | Can damage flowmeter components, affecting durability and accuracy. | Ultrasonic, electromagnetic with corrosion-resistant liners, special coatings (Hastelloy, titanium) |

| Scaling & Deposits | Cause flow obstruction and measurement errors. | Ultrasonic, electromagnetic |

| Phase Changes & Multiphase Fluids | Presence of gas bubbles, solids, or phase transitions complicate measurement. | Coriolis, differential pressure, vortex |

Tip: Always match your meter type to your fluid’s properties. This step helps you get accurate flow measurements and reduces maintenance needs.

Determine Flow Range and Pipe Size

You must know your flow range and pipe size before you choose a meter. The flow range means the lowest and highest flow rates you expect in your system. Pipe size affects which meter types will fit and work well. If you pick a meter that does not match your pipe size or flow range, you risk getting wrong readings or damaging your meter.

Small pipes need meters that fit tight spaces, like micro-ultrasonic or Coriolis meters. Larger pipes work better with ultrasonic or magnetic meters. You should always check the meter’s range to make sure it covers both your minimum and maximum flow rates. If your system might grow in the future, add a safety margin above your highest expected flow.

Here is a table to guide you:

| Pipe Size (mm) | Recommended Meter Types | Unsuitable Meter Types | Reason |

|---|---|---|---|

| 6-15 | Micro-ultrasonic, Coriolis | Turbine, Vortex | Space constraints |

| 15-25 | Ultrasonic, Positive Displacement | Orifice Plate | Accuracy needs |

| 25-50 | Ultrasonic, Magnetic | Large Insertion Meters | Flow profile distortion |

When you install a meter, you need enough straight pipe before and after the meter. This helps the flow stay steady and improves accuracy. For example, ultrasonic meters need about 10 pipe diameters upstream and 5 downstream. Coriolis meters do not need straight runs. If space is tight, use flow conditioners to help.

Designers sometimes oversize pipes for future needs. This can cause solids to settle and give false readings. You can use reducers to increase velocity and keep solids moving. Always match your meter to your pipe and flow range for reliable results.

Note: Proper sizing and installation help you avoid costly mistakes and keep your measurements accurate.

Define Required Accuracy and Repeatability

You must decide how precise your measurements need to be. Accuracy means how close your meter’s reading is to the true flow value. Repeatability means your meter gives the same reading every time under the same conditions. Both matter for good flow meter accuracy.

Some jobs need very high accuracy, like billing or mixing chemicals. Other jobs, like rough flow checks, can use lower accuracy. You should set your accuracy needs based on your application. For example, trade measurement or pharmaceutical mixing needs high-accuracy options. General flow estimation can accept lower accuracy.

Accuracy is usually shown as a percentage, like ±2% of the reading. Repeatability is often better than 0.2% of full scale. You should check accuracy and repeatability at low, normal, and high flow rates. Higher accuracy meters cost more, so balance your needs with your budget.

If you need accurate flow measurements, pick a meter that meets your accuracy and repeatability needs. This choice helps you avoid errors and keeps your process running smoothly.

Tip: Always specify your accuracy and repeatability needs before you buy a meter. This step helps you choose the right meter for your application needs.

Assess Installation Environment (Space, Orientation, Power)

You need to look closely at your installation environment before choosing a water flow meter. The space around your pipes, the way your pipes are set up, and the power supply all affect your decision. If you ignore these factors, you may face problems with accuracy, maintenance, or even safety.

- Make sure you have enough space around the meter for wiring and regular maintenance. Tight spaces can make installation hard and increase costs for extra piping or supports.

- Keep the flow meter away from strong electrical equipment, high-frequency devices, and switching power supplies. These can cause signal interference and reduce accuracy.

- Always install the meter away from high-power motors. Motors can create electromagnetic interference that affects electronic meters.

- Maintain proper grounding for the flow meter. Good grounding helps prevent signal problems and keeps your readings accurate.

- Check that the pipe stays full at the installation point. If air pockets form, your meter may give false readings.

- Follow the correct flow direction and straight pipe length requirements. Some meters need long straight runs before and after the meter to ensure steady flow and high accuracy.

- Think about the power supply. Some meters use batteries, some use AC power, and others use loop power. The type you choose affects both installation and long-term operating costs.

- Consider environmental conditions like temperature, humidity, vibration, and exposure to chemicals. These factors can impact the meter’s performance and accuracy.

Tip: Plan your installation to avoid interference and make future maintenance easy. This step helps you keep your flow meter working well and ensures reliable accuracy.

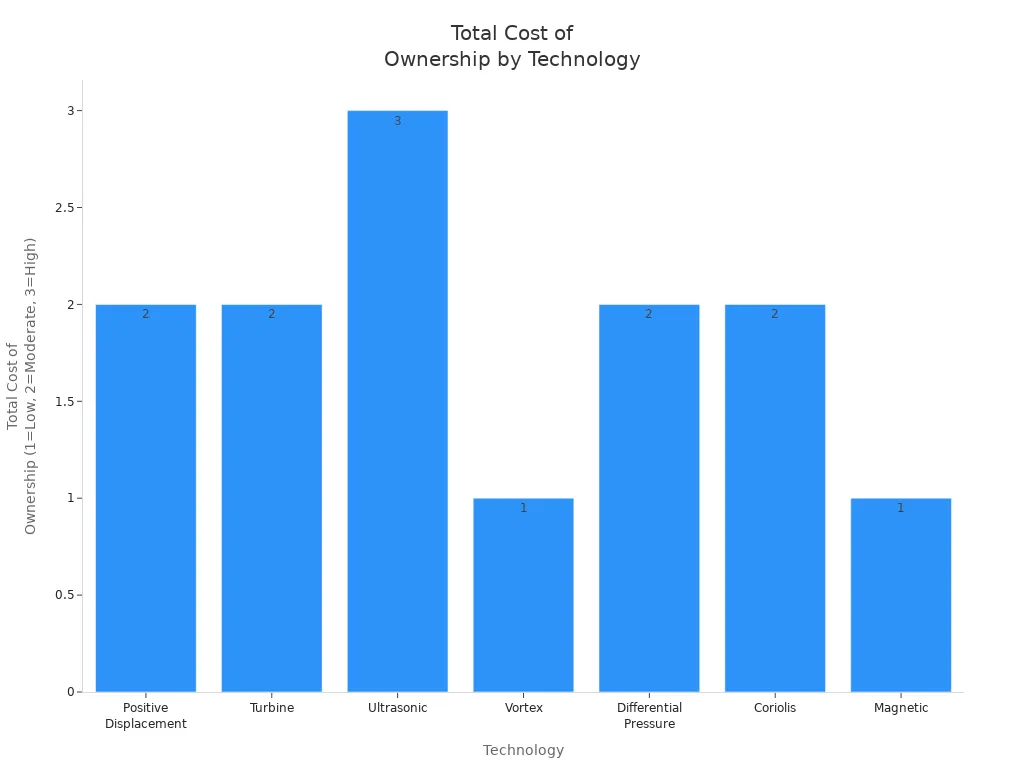

Consider Budget and Total Cost of Ownership

You should not focus only on the purchase price when selecting a water flow meter. The total cost of ownership (TCO) includes the initial cost, installation, maintenance, calibration, downtime, and replacement. Different meter technologies have different TCO profiles. You need to balance your budget with your accuracy and application needs.

Coriolis flow meters cost more at first, but they last a long time and need little maintenance. This makes them a smart choice for high-precision or harsh environments. Magnetic flow meters have moderate to high initial costs and low maintenance, which works well for corrosive or abrasive fluids. Venturi meters have lower initial costs and are very durable, making them good for large-scale water distribution. Clamp-on ultrasonic meters have moderate initial costs and very low installation and maintenance costs, which is great for temporary or retrofit jobs.

Trevor Forster from Titan Enterprises points out that the purchase price is only a small part of the total cost. Downtime, maintenance, recalibration, and replacement cycles can add up. Ultrasonic and Coriolis meters, even with higher upfront costs, lower your TCO because they need less maintenance and last longer. Turbine and positive displacement meters cost less at first but need more frequent maintenance and recalibration, which increases TCO over time.

Here is a table to help you compare different technologies:

| Technology | Initial Cost | Total Cost of Ownership | Accuracy | Maintenance Requirements | Typical Applications |

|---|---|---|---|---|---|

| Positive Displacement | Moderate ($$) | Moderate ($$) | 0.1%-2.0% | Frequent maintenance required | Custody transfer, batching, chemical injection, fuel measurement, high pressure |

| Turbine | Low ($) | Moderate ($$) | ~0.25% | Frequent maintenance required | Custody transfer, batching, process control, blending |

| Ultrasonic | High ($$$) | High ($$$) | 1%-2% wetted, 3%-10% non-invasive | Reduced maintenance | Custody transfer, precision batching, continuous process control, utility metering |

| Vortex | Moderate ($$) | Low ($) | 0.65% liquid, 1.0% gas | Low maintenance, no calibration required | Steam, gas, liquid measurement, batching, utility metering |

| Differential Pressure | Low ($) | Moderate ($$) | ~1% | Calibration needed, potential installation complexity | Custody transfer, batching, process control |

| Coriolis | High ($$$) | Moderate ($$) | 0.05% | Low maintenance | Custody transfer, precision batching, chemical injection, blending |

| Magnetic | Moderate ($$) | Low ($) | 0.15% | Low maintenance | Conductive fluids, wastewater treatment, chemical processing |

Note: Always consider the long-term costs, not just the price tag. A meter with higher accuracy and lower maintenance can save you money over time.

Evaluate Maintenance and Service Needs

You need to think about how much care your flow meter will need. Maintenance affects both accuracy and the total cost of ownership. Some meters need frequent cleaning, calibration, or part replacement. Others work for years with little attention.

Common maintenance issues include:

- Air pockets in pipelines can disrupt flow readings. You can solve this by installing air eliminators or placing meters where air cannot collect.

- Pipe blockages or deposits from scale or sediment can lower accuracy. Regular inspection, cleaning, and filtration help prevent this.

- Temperature and pressure changes can affect accuracy. Use meters with compensation features or choose types that handle these changes well.

- Signal interference in electronic meters can come from electromagnetic fields or poor grounding. Use shielded cables and proper grounding to protect accuracy.

- Sensor blockage from debris or foreign particles can cause inaccurate readings. Upstream filters or strainers help keep sensors clean.

- Mechanical failures, such as worn gears or paddles, need regular checks and part replacement.

- Improper installation can expose meters to vibration, moisture, or contaminants. Always follow installation guidelines to avoid these problems.

You should schedule regular inspection, cleaning, and calibration. Preventive maintenance, like leak checks and performance tests, helps you catch problems early. In industries with lots of buildup, such as food or pharmaceuticals, plan for more frequent cleaning.

Tip: Choose a flow meter that matches your maintenance skills and schedule. This helps you keep accuracy high and avoid costly downtime.

Check Output and Signal Requirements (Analog, Digital, Data Logging)

When you select a water flow meter, you must check the output and signal options. These features help you connect your flow sensor to other systems for real-time flow monitoring, control, and data collection. The right output lets you track water use, spot leaks, and plan maintenance.

Modern water flow meters offer several output types. Each type fits different needs:

- Pulse Output: The meter sends a quick electrical pulse for each set amount of water that passes through. You can use this signal with simple counters or connect it to a data logger. Pulse outputs work well for totalizing flow or triggering alarms.

- Analog Output (4-20 mA): The meter sends a continuous electrical signal that changes with the flow rate. You can connect this output to a chart recorder, PLC, or SCADA system. Analog signals are common in industrial settings because they are easy to use and reliable over long distances.

- Digital Output (RS485, Modbus, or similar protocols): The meter sends flow data in digital form. You can connect digital flow meters to computers, SCADA, or building management systems. Digital outputs support advanced features like remote monitoring, data logging, and leak detection.

You often see these output options in modern flow meters:

- Paddlewheel, ultrasonic, and magnetic meters with chemical-resistant materials and digital displays.

- Standard outputs that support SCADA or PLC systems for easy integration.

- Digital flow meters with built-in data logging and remote access.

- Historical trend data that helps you plan maintenance and manage resources.

- Integration with digital systems for remote data collection and leak detection.

Here is a table to help you compare common output and signal options:

| Output Type | Description | Typical Use Cases | Integration Example |

|---|---|---|---|

| Pulse | Sends a pulse per unit of flow | Totalizing, batching, leak alarms | SCADAmetrics EMP Signalizer |

| Analog (4-20 mA) | Continuous signal based on flow rate | Process control, monitoring, automation | PLC, chart recorder |

| Digital (RS485, Modbus) | Digital communication for flow data | Remote monitoring, data logging, SCADA | Schneider PowerLogic ION, SCADA |

You should also think about how your flow meter will connect to your data logging system. Many meters now support direct integration with SCADA or telemetry systems. This setup lets you collect flow data, track trends, and respond to problems quickly. For example, the Mueller HbMag magnetic flow meter provides multiple signal outputs for municipal water systems. It supports both totalization and flow rate monitoring and connects easily to SCADA for data collection and control.

Some meters, like clamp-on ultrasonic types, allow you to install them without cutting pipes. This feature makes it easy to add real-time flow monitoring to existing systems. Inline electromagnetic meters need careful installation to keep accuracy high, but they offer strong integration with digital systems.

You should always match your output and signal needs to your application. If you want simple flow tracking, a pulse output may be enough. For advanced monitoring and control, choose a meter with analog or digital outputs and data logging. Proper installation and regular maintenance help you collect reliable data and keep your system running smoothly.

Tip: Always check if your flow meter supports the output type your system needs. This step ensures easy integration and accurate monitoring.

Practical Example: Flow Meter Selection for an Industrial Cooling System

Application Overview

You manage an industrial cooling system that keeps equipment at safe temperatures. Cooling towers and circulating water systems need accurate flow measurement to prevent overheating and reduce energy costs. You use flow meters to monitor water flow, detect leaks, and spot pump failures. These meters help you make data-driven decisions for maintenance and operation. In this environment, you often measure flows like condenser water, blow down, and make-up water. You also face installation challenges, such as limited straight pipe length and the need to avoid system shutdowns.

Monitoring flow rates in your cooling system helps you extend equipment life and improve safety by preventing hazards like pipe bursts.

Applying the Flow Meter Selection Criteria

You can follow a step-by-step process to choose the right industrial flow meter:

- Identify the fluid type. You measure water, which is conductive and has stable density.

- Evaluate fluid characteristics. Check for temperature changes, pressure, and possible scaling or corrosion.

- Determine the flow range. Find the minimum and maximum flow rates in your system.

- Assess the installation environment. Look at space, humidity, and possible electromagnetic interference.

- Consider flow meter types. Magnetic flow meters work well for conductive water. Ultrasonic meters offer non-intrusive installation. Turbine meters provide reliable readings for clean water.

- Review installation needs. Make sure you have enough straight pipe and proper valve placement.

- Analyze costs. Include purchase, installation, and maintenance in your decision.

You also need to think about how the meter will connect to your building automation system. Many meters use Modbus or BACnet protocols for easy integration.

Final Choice and Rationale

You select an insertion electromagnetic flow meter for your industrial cooling system. This meter has no moving parts, so it handles typical cooling tower water quality and needs little maintenance. It offers ±1% accuracy and works well with conductive water. If you cannot shut down the system, you might choose a clamp-on ultrasonic meter for non-intrusive installation. Both options support digital outputs for integration with your automation system.

You make this choice because you need reliable, repeatable measurements to track efficiency and prevent equipment problems. The selected industrial flow meter fits your fluid properties, installation limits, and data needs. You ensure safe, efficient cooling and support long-term operational success.

Quick Reference Checklist for Flow Meter Selection

You can use this checklist to make sure you select the best water flow meter for your needs. This guide helps you avoid common mistakes and ensures your choice fits both technical and regulatory requirements.

-

Define Your Application

- Identify if your use is residential, commercial, or industrial.

- Set your flow range and accuracy needs.

- Think about environmental conditions, such as temperature and humidity.

- Decide if you need the meter for billing and regulatory purposes.

-

Analyze Fluid Properties

- Check if the water is clean, dirty, or contains chemicals.

- Exclude meter types that do not work with your fluid.

-

Confirm Flow Range and Pipe Size

- Measure your minimum and maximum flow rates.

- Match the meter to your pipe diameter.

-

Determine Accuracy and Compliance

- Choose a meter that meets your accuracy needs.

- Make sure the meter has the right certifications for compliance with local standards.

-

Assess Installation Environment

- Look at available space and pipe orientation.

- Check if you can install the meter without shutting down the system.

- Prepare the pipe by removing debris and ensuring straight runs.

-

Evaluate Cost and Certification

- Compare upfront price and long-term costs.

- Verify the meter meets all compliance and safety standards.

-

Check Signal Transmission and Integration

- Confirm the meter’s output matches your data collection system.

- Make sure it supports your communication protocols.

-

Plan for Maintenance

- Set a schedule for monthly checks and annual inspections.

- Include cleaning and recalibration in your plan.

Tip: Always match the flow meter type to your specific application. For example, in residential settings, you may need a simple meter for water use tracking, while industrial sites may require advanced features for compliance and data integration.

| Step | What to Check | Why It Matters |

|---|---|---|

| Application | Residential, industrial, billing needs | Ensures correct meter type |

| Fluid Properties | Clean, dirty, chemical content | Excludes incompatible meters |

| Accuracy & Compliance | Precision, certifications | Meets billing and regulatory purposes |

| Installation | Space, shutdown feasibility | Smooth setup, less downtime |

| Cost | Upfront and long-term | Budget planning |

| Signal Transmission | Output compatibility | Data integration |

| Maintenance | Schedule, ease of service | Long-term reliability |

Selecting the best water flow meter starts with a clear process. You should:

- Identify your fluid type and its properties.

- Define your measurement needs and accuracy.

- Assess pipe size and installation space.

- Review environmental conditions.

- Plan for maintenance and total cost.

- Choose a trusted manufacturer.

Matching the meter to your application ensures reliable results.

For complex or unique needs, reach out to technical experts. They can help you find the right solution for your system.

FAQ

What is the most important factor when choosing a water flow meter?

You should always match the meter type to your fluid properties. Clean water works with most meters. Dirty or corrosive water needs special types. This step helps you get accurate results and reduces maintenance.

How often should you calibrate your water flow meter?

You should check calibration once a year. Some meters need more frequent checks if you use them in harsh environments. Regular calibration keeps your readings accurate and helps you spot problems early.

Can you install a flow meter without shutting down your system?

Yes, you can use clamp-on ultrasonic meters. These meters attach to the outside of the pipe. You do not need to cut the pipe or stop the flow. This method saves time and avoids downtime.

What output signals do most modern flow meters support?

Most modern flow meters support pulse, analog (4-20 mA), and digital (Modbus, RS485) outputs.

You can connect these signals to data loggers, PLCs, or SCADA systems for easy monitoring.

How do you reduce maintenance needs for your flow meter?

You should choose a meter with no moving parts, like electromagnetic or ultrasonic types.

- Install filters to keep debris out.

- Schedule regular inspections.

- Follow the manufacturer’s cleaning and calibration guidelines.